3D scanning services is a process of collecting digital data on the shape and appearance of a physical object, creating a digital model of it. This can be done using a variety of technologies, such as structured light scanners, laser scanners, and photogrammetry.

Laser 3D scanning is a method of capturing precise 3D data using a laser as the main measurement tool. A laser beam is projected onto an object’s surface, and a sensor measures the reflected light. By calculating the time it takes for the laser to return, the scanner determines the distance to each point. Repeating this process creates a detailed 3D model. Laser scanners, available in handheld or fixed setups, accurately scan objects of various sizes and shapes with high precision.

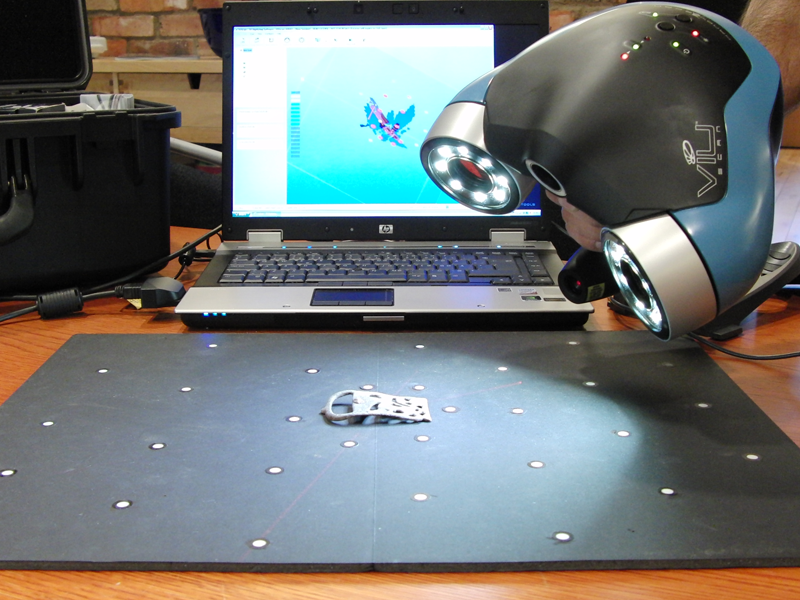

Structured light scanners use a projector to cast a pattern of light and shadows onto an object’s surface. A camera captures the distorted pattern, and the scanner analyzes this deformation to calculate the distance from each point on the object. This process builds an accurate 3D model. Structured light scanners are available in handheld or fixed setups and are versatile enough to scan objects of various sizes and shapes with precision, making them ideal for diverse industrial and design applications.

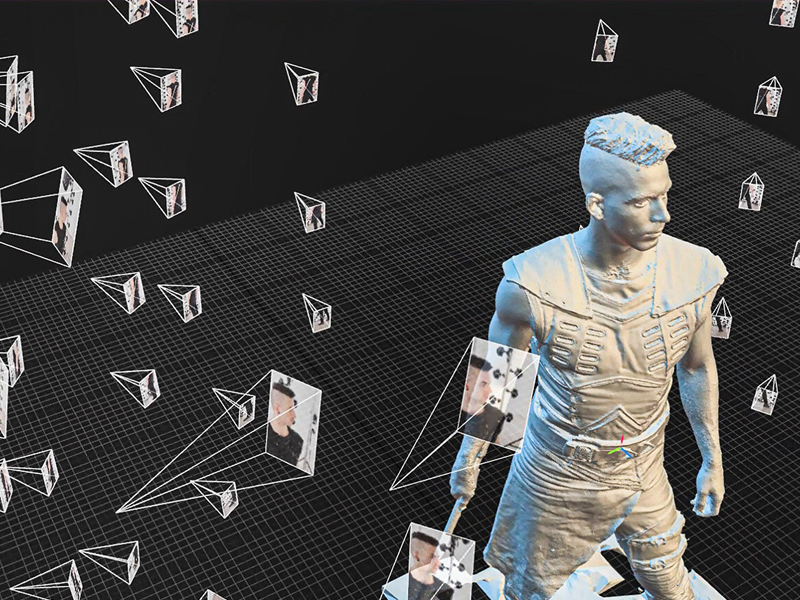

Photogrammetry 3D scanning is a process of collecting 3D data by taking a series of overlapping photographs of an object or scene from different angles and using specialized software to process the images and calculate the 3D positions of the points in the scene. This process allows the creation of a 3D model of the object or scene. Photogrammetry 3D scanning can be done using specialized cameras or with the cameras on devices such as drones or smartphones.

3D Scanning Car

Automotive companies use 3D scanning for reverse engineering, quality control, inspection, new product development for production parts, and manufacturing tools. A wide range of EMOs and automotive part suppliers are involved in designing, developing, and manufacturing motor vehicles. They are meeting the challenge of designing cars in a short amount of time to meet the fast-paced growth of the market. Cutting-edge technologies, including 3D scanning, are what they seek to reform the automotive industry.

3D Scanning Aircraft

The aerospace industry demands precision, safety, and efficiency. 3D scanning enhances design, testing, and manufacturing by providing accurate, detailed views of aircraft parts. It helps identify and fix issues early, reducing costly errors and improving quality. The technology also supports reverse engineering, enabling the recreation of legacy parts or development of new ones. With 3D scanning, aerospace manufacturers can accelerate innovation, ensure safety, and meet the industry’s high standards.

3D Scanning Jewelry

3D scanning jewelry, precious metals, and gemstones enables the creation of highly accurate digital copies for repair, duplication, or design purposes. Our advanced 3D scanner is engineered to capture small, intricate objects with exceptional precision. It records up to 16 million data points per scan, ensuring detailed measurement of complex shapes and fine surface features. This technology preserves delicate designs and supports high-quality reproduction, ideal for jewelers, designers, and restoration professionals.

3D Scanning Dental

3D scanning technology is widely applied to medical beauty, medical equipment, biomedical engineering, orthopedics surgery, digital dentistry, etc., gradually becoming the foundation of technical innovation in the medical field. eCadCam provides integrated and precise 3D Solutions for surgeons, health care professionals, and medical equipment manufacturers. Our goal goes to help them easily confront challenges and grasp opportunities in 3D Printing prosthesis model manufacturing, medical machinery customization, quality control etc.

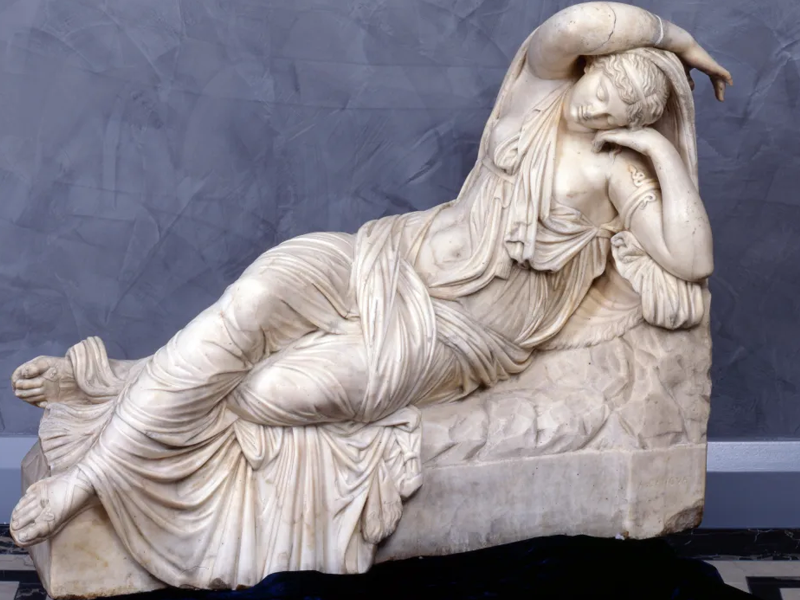

3D Scanning Sculpture

3D digitization is widely used for preserving cultural relics, building digital museums, and designing handicrafts. 3D scanning offers the fastest method for reconstruction, with user-friendly and portable scanners capturing detailed data from various angles. This technology provides fast, accurate measurements of artifacts like sculptures and artworks. In cases of accidental damage, experts can virtually restore relics using 3D models, supporting research and preservation efforts through digital tools and virtual reconstruction techniques.

3D Scanning Shoe

3D laser scanning is revolutionizing retail by enabling personalized, better-fitting, and more sustainable products. Many people struggle to find shoes that match their unique foot shapes—differences in size, width, or fit often make shopping frustrating. 3D scanning solves this by capturing precise measurements, allowing brands to offer customized footwear tailored to each customer. This improves comfort, satisfaction, and loyalty, setting a new standard in how consumers interact with products and brands.

Reverse engineering is the process of developing a CAD model from a physical part. In the automotive space, this is typically used for legacy parts and tooling for vehicles no longer in production. Historically, this process would be accomplished through manual measurement, 3D scanning creates a digital copy of the object, allowing the measurement work to be done by software tools.

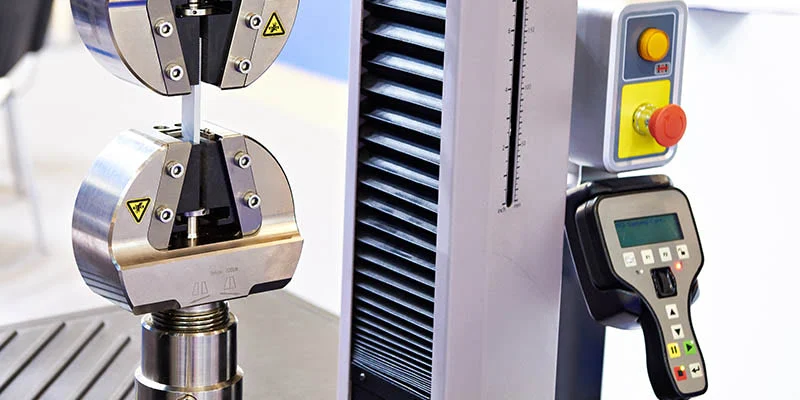

Inspection, a process to ensure that products are free from defects, is essential for manufacturing, especially for high-precision parts. The requirements for inspection are increasing as the manufacturing technology improves. Traditional methods are time-consuming and not efficient to inspect due to their limited uses and troublesome operations. It is hard for them to obtain complete data on complex parts, and they fail to measure ductile parts or parts with curved surfaces. The advent of 3D scanning technology has greatly alleviated these pain points.

eCadCam offers white light, blue light and laser scanning. Our engineers will choose the technology that best meets your needs for reverse engineering or inspection. Our 3D experts will work with you to figure out which machine best fits your needs based on size, portability, and accuracy.

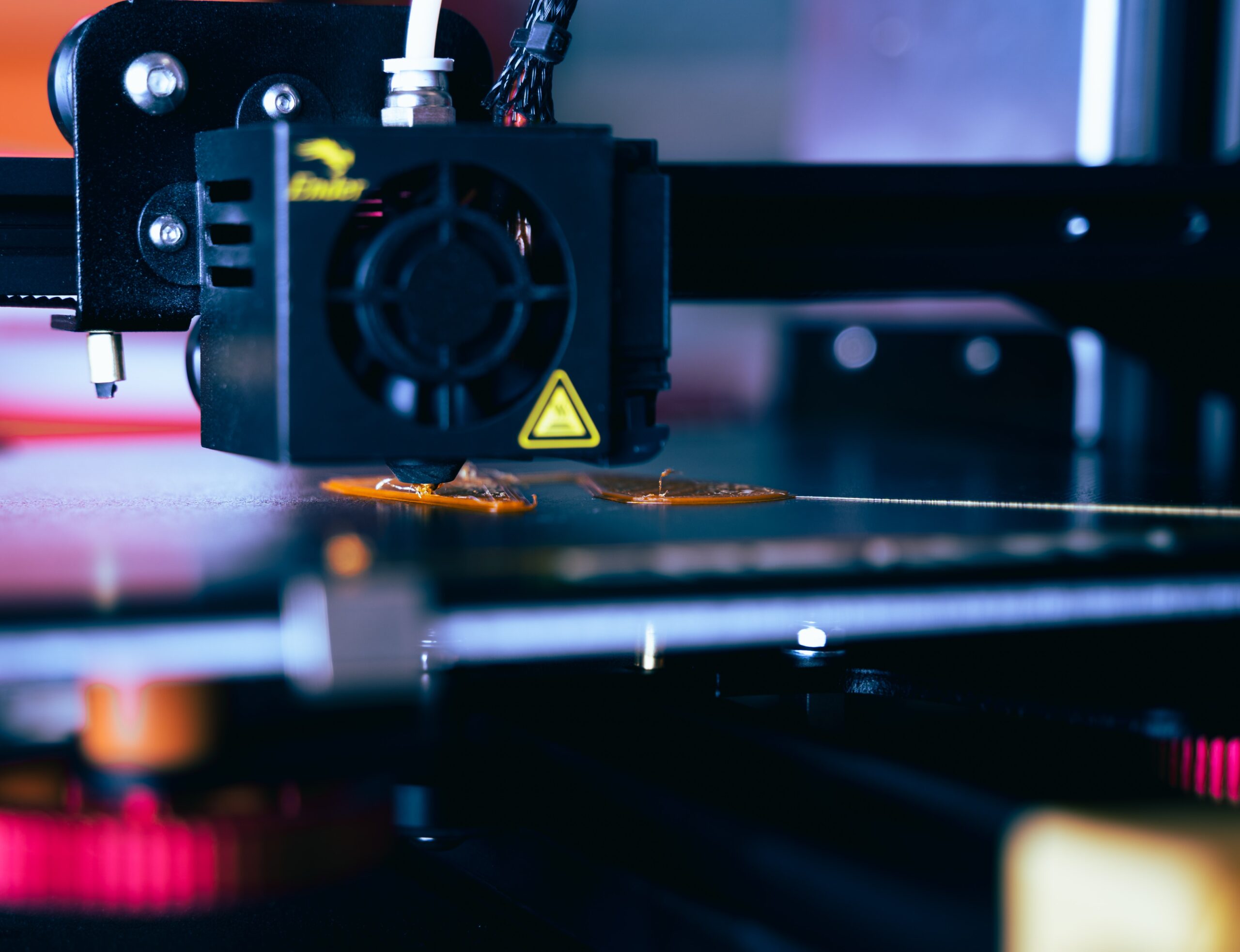

3D scanning is generally the first step in reverse engineering complex parts. The ultimate goal of reverse engineering is generally to create a 3D CAD (Computer Aided Design) model for use in the customer’s design system.

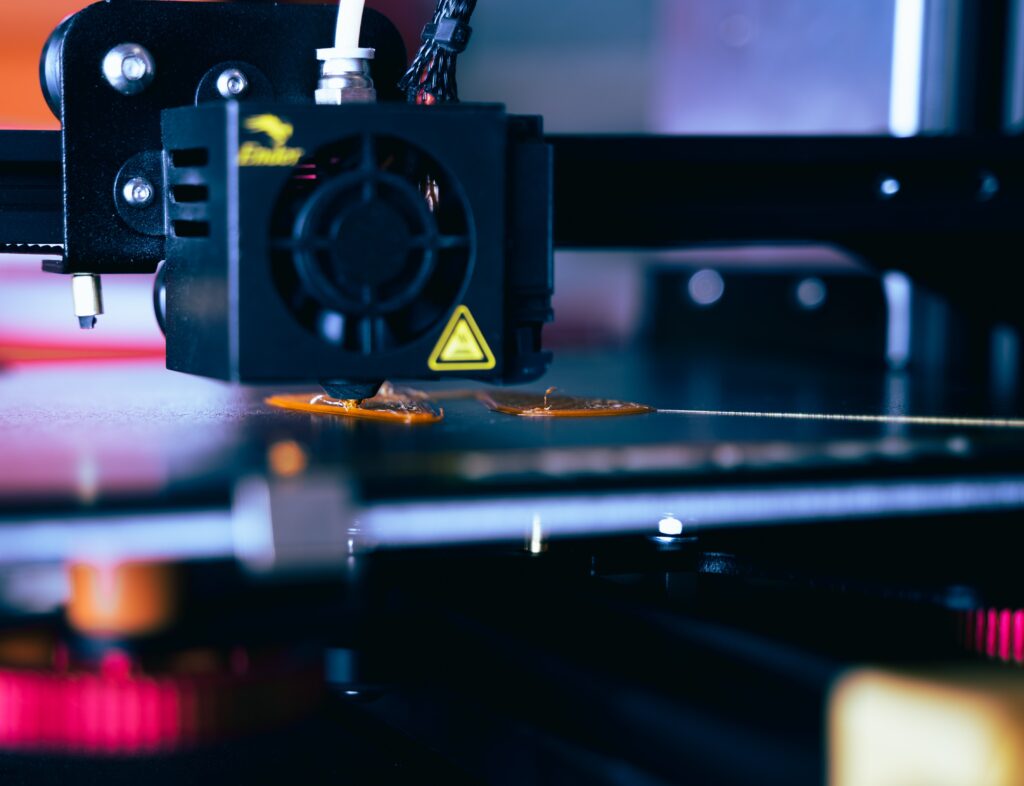

3D scanning refers to the rapid capture of data in order to define complex shapes utilizing optical technology. The 3D Scanners employs some type of optical projection, either laser or structured light, and one or more cameras. The cameras detect pixels along the projected stripes in order to triangulate data points along each stripe.

We use powerful software tools to convert raw data sets into high-quality 3D CAD models, or to compare the scan of your part to your original design in a comprehensive inspection report.

Send the parts to us, or we’ll come to you. Many of the systems that we employ are fully portable, allowing our teams to travel to remote locations to scan parts that are too large or heavy to ship to our facilit

A parametric model is composed of primitive geometric features, trimmed surfaces, fillets & radii. Geometry is developed using traditional solid modeling techniques such as sketching and extruding, using the underlying scanned data as a reference.

We are a Los Angeles–based 3D technology studio specializing in 3D printing, 3D scanning, laser cutting, and laser engraving. With over two decades of experience, we help businesses, artists, and designers turn concepts into reality with precision, speed, and quality craftsmanship.

From jewelry and product design to film props and industrial parts, our team delivers high-resolution results tailored to each client’s vision. Every project is completed with accuracy, attention to detail, and fast turnaround — all from our fully equipped Los Angeles studio.